* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

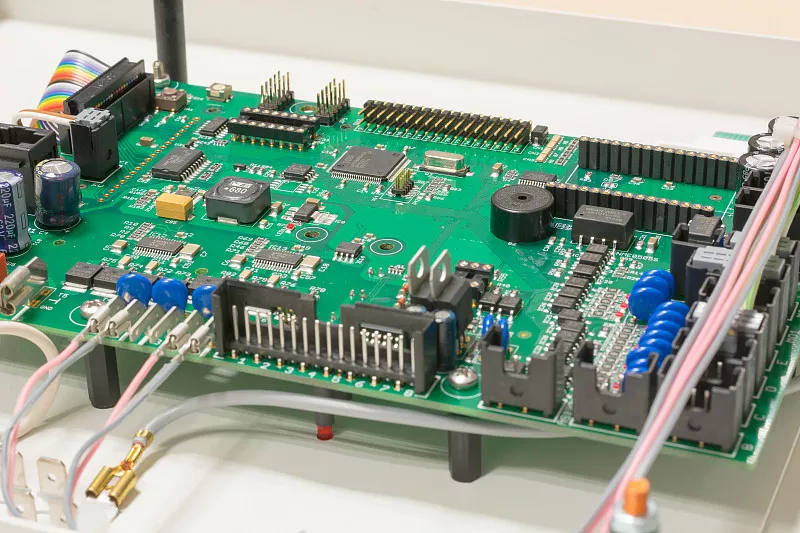

We are fully committed to providing continuous solution services for printed circuit boards, including design, assembly, and manufacturing. Once the PCB design is finalized, there are certain files that need to be exported to ensure proper PCB assembly. If you require turnkey assembly manufacturing and inquiry, you will need BOM (bill of materials), centroid data, and PCB designs, which can be in either ODB++ or Gerber format.

In addition to the above files, it is helpful to include additional files such as assembly drawings or fabrication drawings, as well as any specific instructions for the project. We also offer preliminary quotes based on early Gerber files if the design is not yet complete. In this article, we will discuss how to generate files for PCB assembly and the important things to consider during PCB assembly. Please read on to gain a better understanding.

(1) Good stability and reliability of solder paste. The content of harmful impurities is strictly controlled for the solder; low residue and non-corrosive for the solder paste and flux; the bonding strength is not high or low for the bonding agent, so as to ensure that the chip will not drop during the soldering process, but also Easily take off during maintenance.

(2) Equipment that can meet the needs of high-speed production. The SMT production process is generally a high-speed automated process, and the process materials should be adapted to it. For example, the curing time of the bonding system was about 20 minutes when the oven intermittent curing method was used in the middle and late 1980s, and the continuous curing method of the tunnel furnace commonly used in the 1990s required the curing time to be within 5 minutes, and progress is required It has a shorter curing time than before.

(3) It can meet the needs of fine pin pitch and high density assembly. Fine pin spacing and high-density assembly require the alloy solder powder in the solder paste to have a finer particle size; require better thixotropy and smaller slump of the solder paste and binder; strict control of the solid content and activity in the flux is required to avoid Defects such as bridging have occurred.

(4) It can meet ROSH environmental protection requirements. Many materials in traditional SMT process materials contain substances that are harmful to the atmospheric ozone layer and the human body, such as cleaning agents containing chlorofluorocarbons (CFCs) and lead-containing solders. With the increasing awareness of human environmental protection and increasing human health Attention, the research work of harmless SMT process materials is being continuously strengthened.

To ensure that we can assemble your printed circuit boards accurately, we strongly advise you to send all relevant documents and information related to the boards to us. This may include your assembly drawings, special assembly instructions, and even images or photos of your work. Providing us with this information will help us better understand your assembly requirements, identify and correct any ambiguous or incorrect placements, and ultimately deliver an excellent result. Although it is not usually required by assemblers, please send this information to us for best results.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108