* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

The 6S lean management originates from methodology created by the Toyota Production System between the years of 1948 and 1975. This procedure enabled the Japanese company to produce higher quality products faster with less waste and inventory than the competitors.

While the fundamentals of 6S management were created decades ago, the benefits of the methodology persist even in today’s conditions. So, what are the core principles of the 6S in manufacturing?

In order to ensure efficient and orderly production, companies will formulate relevant systems that suit their own development needs, and the "6S" system is often the core of the formulation.

1. Seiri

Purpose:

a.Improve and increase the working area;

b.There is no debris on the site, and the roadway is unobstructed to improve work efficiency;

c.The chance of bumping is reduced, safety is ensured, and quality is improved;

d.Eliminates the management of mixing, mixing, etc. Mistakes;

e. Conducive to reducing inventory and saving money; f. Changing work style and improving work mood.

2. Seiton

Definition: Necessities are positioned according to regulations, arranged in a neat and orderly manner, and clearly marked.

Purpose: Do not waste time searching for items, improve work efficiency and product quality, and ensure production safety.

3. Seiso

Definition: Remove dirt from the site and remove material waste in the work area.

Purpose: Keep the scene clean and bright.

Significance: Removal of dirt in the workplace makes it easy to find the source of abnormality. It is the first step in implementing autonomous maintenance, mainly to improve equipment utilization.

4. Seiketsu

Definition: Institutionalize and standardize the implementation of sorting, rectification, and cleaning, and maintain its results.

Purpose: Carefully maintain and insist on sorting, rectifying, and cleaning to keep it in the best condition.

Significance: Through persistence and deepening of sorting, rectification, and cleaning activities, the root causes of safety accidents can be eliminated. Create a good working environment so that employees can work happily.

5. Shitsuke

Definition: Everyone operates in accordance with the rules, acts in accordance with the rules, develops good habits, and everyone becomes an educated person.

Purpose: To improve the "quality of people" and cultivate people who are serious about any work.

Significance: It is the core of the "6S" activity to strive to improve the personnel's self-cultivation and to develop the habit and style of strict compliance with the rules and regulations.

6. Safety

Definition: Discover potential safety hazards and eliminate them in time or strive for effective preventive measures.

Purpose: To establish a safe production environment, all work should be established on the premise of safety.

Significance: Protect personnel and goods from infringement, and create a work site without accidents.

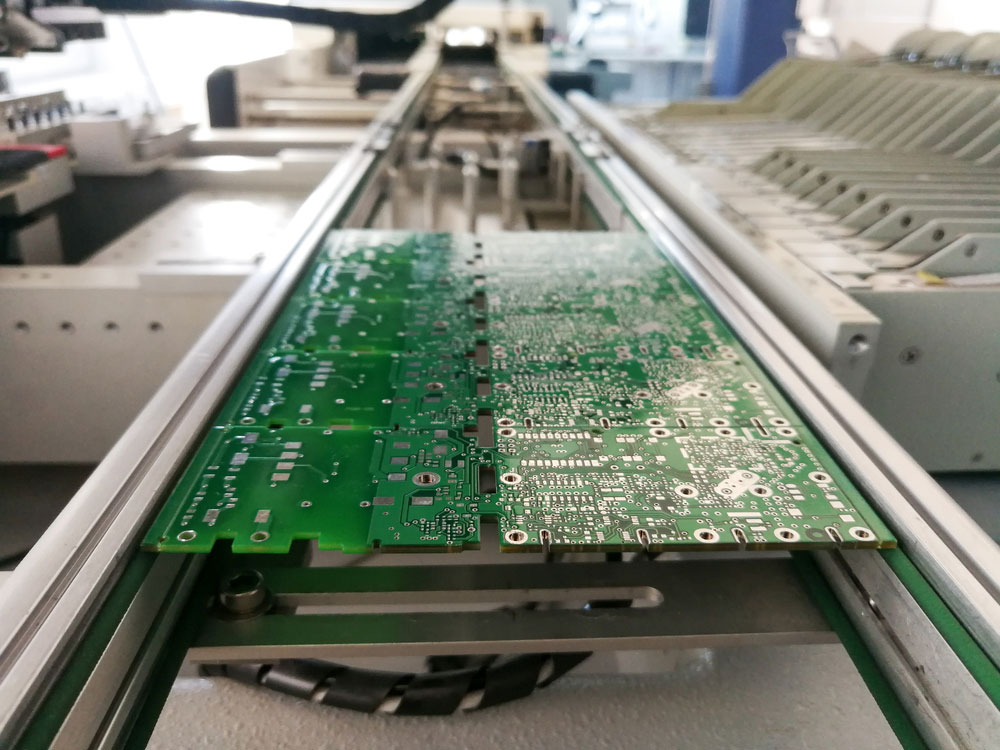

SHEN ZHEN Kingsheng PCBA TECH.Co,.Ltd. since its establishment in 2008 has kept providing One-stop PCB Assembly Service and Electronics Manufacturing Service (EMS) in Bao’an District Shenzhen, China for global customers. As ISO 9001, UL, CSA, and CCC certified manufacturer, we offer flexible, cost-effective and high-quality EMS solutions for printed circuit board assembly (PCBA) and complete product assembly through advanced manufacturing technologies and facilities. We are leading PCB assembly manufacturer and printed circuit boards supplier in China. Due to the special and high grade requirements of automotive regulations, it has also contributed to the formation of the company's quality DNA. Over the years, we have been adhering to the business philosophy of quality as the root and service as the soul, providing high-quality EMS for global customers.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108