* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

At present, the industry's testing methods for PCBA boards can be roughly divided into three major parts: AOI, ICT/MDA, and FVT/FCT. In addition, some people use X-Ray to check on the line, but it is not common.

Below we will roughly discuss the capabilities of these three test methods, and because the current three methods have their own advantages and disadvantages, it is difficult to replace the other two with only one method, unless someone thinks that the risk is small and can be ignored.

AOI (Automated-Optical-Inspection):

With the advancement and maturity of imaging technology, AOI is gradually adopted by many SMT production lines. Its inspection method is to use image comparison, so there must be a golden sample that is considered to be a good product and record its image. Then the other boards are compared with the images of the standard model to judge whether they are good or bad.

Therefore, AOI can basically judge whether there are missing parts, tombstones, wrong parts, offset, bridges, empty soldering, etc. on the assembled circuit board; but it cannot identify the soldering properties directly under the parts, such as BGA IC or QFN IC, as for fake welding and cold welding, it is difficult to judge by AOI. In addition, if the characteristics of the part have changed or there are micro cracks, it is difficult to be identified by AOI.

Generally, the misjudgment rate of AOI is very high, and it takes experienced engineers to adjust the machine for a period of time to stabilize. Therefore, during the initial introduction of the new board, a lot of manpower input is required to re-judge whether the problematic board produced by AOI is really problematic.

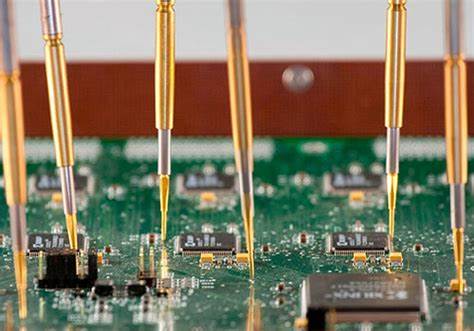

ICT/MDA (In-Circuit-Test/Manufacturing-Defect-Analyzer):

Traditional testing methods. The electrical characteristics of all passive components can be tested through test points. Some advanced test machines can even run the program on the circuit board to be tested and do some functional tests that can be run by the program. If most of the functions can be completed through the program, you can consider canceling the following FVT (functional test).

It can catch missing parts, tombstones, wrong parts, bridges, reverse polarity, and can roughly measure the weldability of active parts (IC, BGA, QFN), but it is not suitable for empty welding, false welding, and cold welding. Certainly, because this kind of solderability problem is intermittent, if it happens to be touched during the test, it will pass.

Its disadvantage is that there must be enough space on the circuit board to place the test points. If the fixture is not designed properly, the electronic parts on the circuit board and even the traces in the circuit board will be damaged due to mechanical actions.

The more advanced the test fixture, the more expensive, some even as high as one million Taiwan dollars.

FVT/FCT (Function Verification Test):

Traditional functional testing methods are usually combined with ICT or MDA. The reason for the need to match ICT or MDA is that the functional test needs to be actually connected to the circuit board. If there is a short circuit on the circuit on some power supplies, it is prone to damage to the board to be tested. In severe cases, the circuit board may even be burned.

It is important to note that the functional test method may not be able to determine if the electronic components meet the original requirements. This implies that the performance of the product cannot be accurately measured. Additionally, some bypass circuits cannot be assessed using the general functional test, which should be taken into consideration.

Although the functional test is capable of detecting weldability issues, faulty parts, bridges, short circuits, and more, it may not always be able to detect problems with the bypass circuit or issues such as empty, false, and cold welding.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108