* On your first PCB Assembly order!

* Up to $300 discount

C - A L L E Y

C - A L L E Y

About Us | Events | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

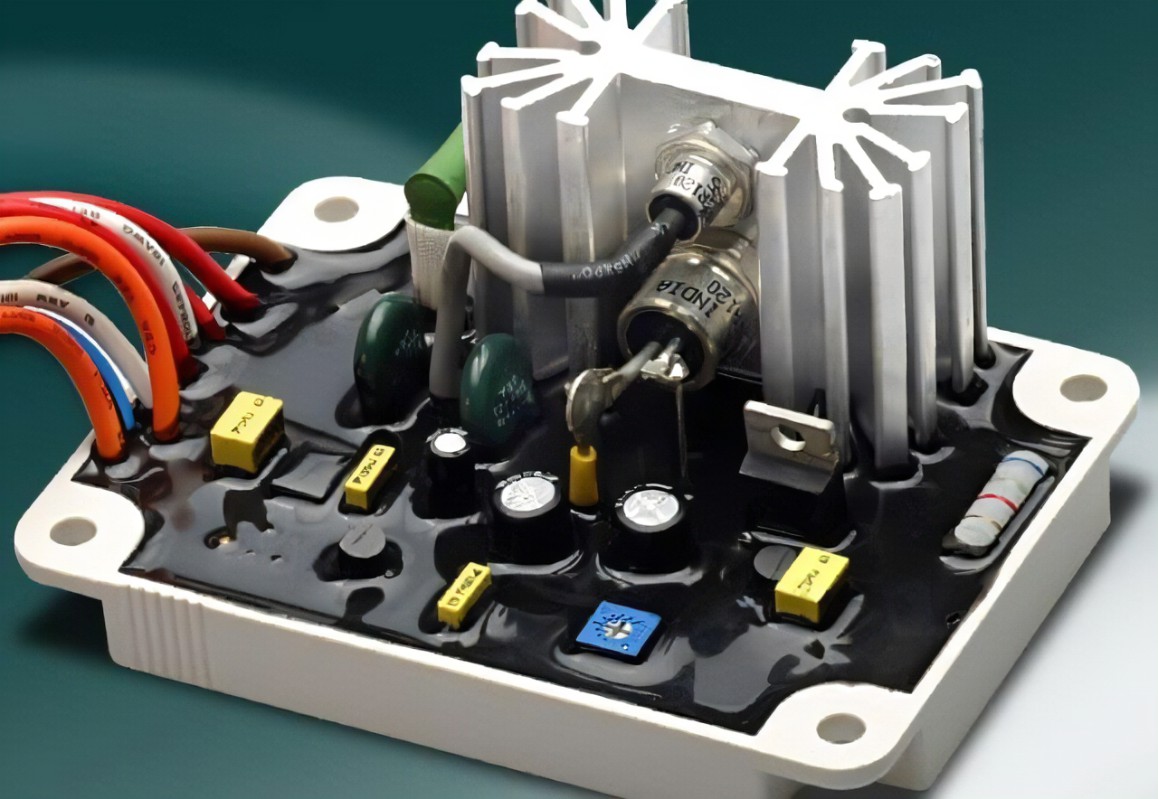

Offering a nearly limitless assortment of end properties, epoxy systems enable higher density semiconductor electronics and economical, as well as enhanced reliability, while improving manufacturing efficiencies.

Today’s high performance electronic circuits that are designed into compact assemblies must meet a host of engineering requirements to ensure the reliability of the system. Advanced packaging technologies, such as flip chip assemblies, bare chip mounting, and ultra-fine pitch technology present challenges in terms of securing components to printed circuit boards (PCBs), preventing short circuits, dissipating heat, and protecting delicate components during the manufacturing process. To address these challenges, manufacturers often select environmentally friendly epoxy compounds that achieve high bond strength while providing other application specific benefits.

Epoxy-based adhesives, encapsulants, and sealants are important components in the manufacturing and assembly of modern electronic systems. They are used in a wide range of applications, from tiny implantable medical devices to large space and defense systems. These versatile compounds can be customized to perform well in challenging environments, such as vacuum, cryogenic, and high-temperature conditions. They can withstand thermal and mechanical stress, moisture, chemicals, and other contaminants. Because of their ability to prevent short circuits, extend joint life, and prevent stress-related failures, epoxies are widely recognized for their contributions to the reliability and longevity of modern electronic systems. By offering a nearly limitless range of end properties, epoxy systems enable the creation of higher-density semiconductor electronics and cost-effective, reliable, and high-performance electronic devices, while improving manufacturing efficiency.

Epoxy compounds are often used for structural bonding in PCB assembly. Die attach adhesives bond components directly onto printed circuitry, protecting components from thermal cycling, mechanical shock and vibrations.

Shenzhen Kingsheng PCBA Tech. is now dedicated to explore new ideas and environmental friendly solutions toward every customized PCBA project.

With epoxy systems, manufacturers can create higher-density semiconductor electronics that are more reliable and cost-efficient, thanks to the nearly limitless assortment of end properties available.

High-performance electronic circuits that are designed into compact assemblies must meet various engineering requirements to ensure the system's reliability. Advanced packaging technologies, such as flip chip assemblies, bare chip mounting, and ultra-fine pitch technology, pose several challenges concerning securing components to printed circuit boards (PCBs), preventing short circuits, dissipating heat, and protecting delicate components during the manufacturing process. To deal with these challenges, manufacturers commonly choose environmentally friendly epoxy compounds that achieve high bond strength while providing other application-specific benefits.

Please send Email to kspcba@c-alley.com or call us through +86 13828766801 Or submit your inquiry by online form. Please fill out below form and attach your manufacturing files( PCB Gerber files and BOM List) if need quotation. We will contact you shortly.

+86 13828766801

+86 13828766801 kspcba@c-alley.com

kspcba@c-alley.com https://www.kingshengpcba.com/

https://www.kingshengpcba.com/ 2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108

2/F, Building 6, Tangtou 3rd Industrial Zone, Tangtou Community, Shiyan Town, Baoan District, Shenzhen, China, 518108