C - A L L E Y

C - A L L E Y

About Us | Company Profile | Company Structure | Management Staff Structure | Market Focus | Company Certification | Our Services

KingshengPCBA is a PCBA manufacturer that specializes in PCBA prototype and large-volume PCB assembly production. Our fabrication services offer a high level of customization to suit all prices and requirements, with high-reliability electronic applications including medical, military, automotive, and telecommunications.

Our EMS services include:

* Project evaluation and cost analysis;

* Parts sourcing and incoming material testing;

* PCB Assembly, PCBA Prototype, PCBA box build;

* BGA SMT mounted, X-ray testing, and BGA repairing;

* PCB Design, PCB Layout, and PCB Fabrication;

* Firmware and software programming and testing;

* Mechanical design and wire harness;

* Shipment and post-sales support.

We have strengthened and evolved to a wide range of designing and manufacturing PCBA products for Industrial Control, Smart Meter, natural gas meter, Medical Instrument, Wireless Intelligent Electronic products.

KingSheng has years combined experiences and professionalism to meet your complicated printed circuit board assembly (PCBA) challenges. Additionally, it is our expertise that we can help customers with BOM optimization and components procurement or collect consigned parts.

Our capability for PCBA:

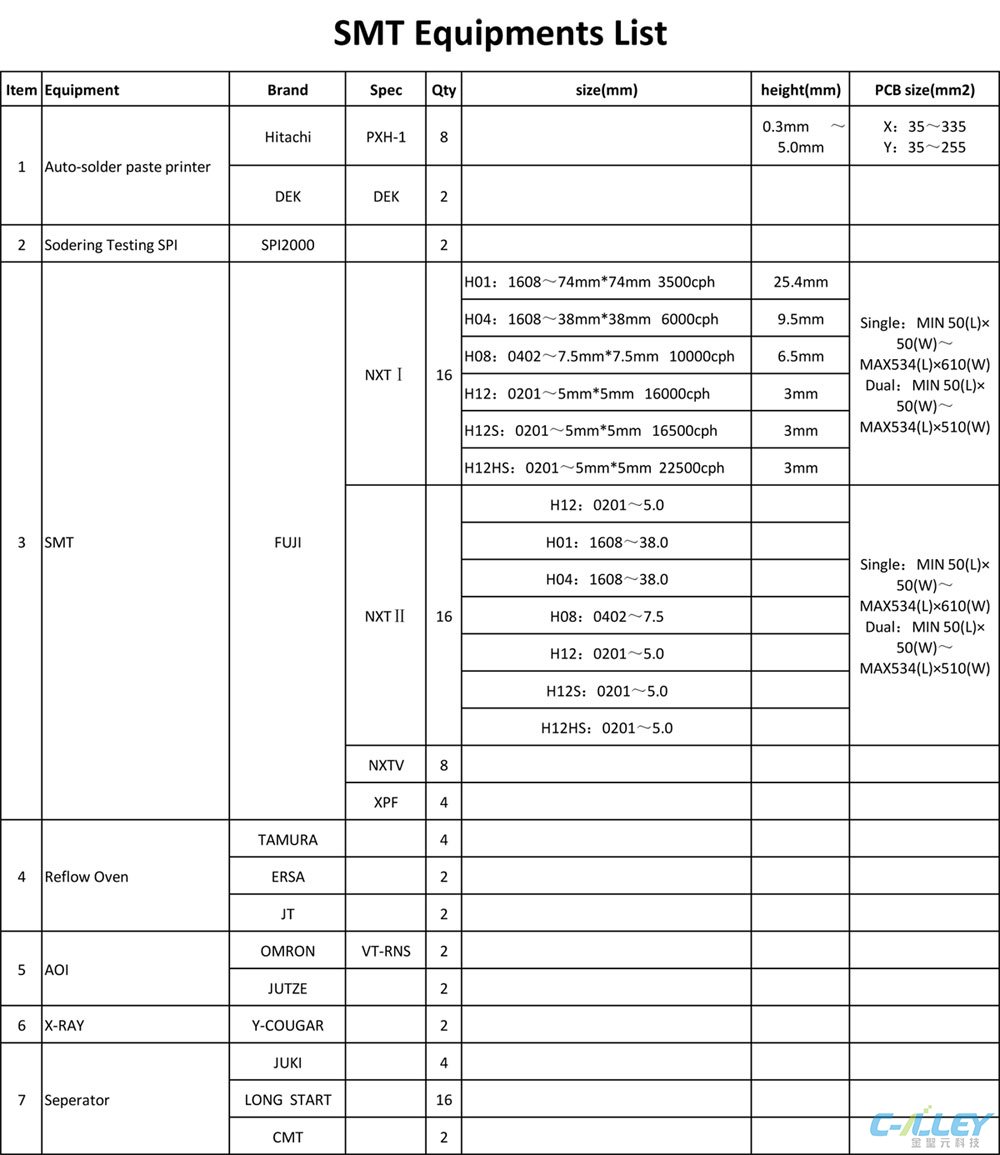

Advanced automatic SMT Equipment:

* HITACHI Screen Printer

* FUJI NXT-Ⅱ& FUJI XPF-L Modules

Assembly Production Machines:

* 8 automatic Fuji modules SMT lines

* 2 DIP Dual wave soldering lines

* 2 manual soldering production lines

Component range:

* 01005,0201,0402,0603,0805,1206,1608,2125,3216

* Fine Pitch QFP to 0.2mm

* BGA, QFP, CSP, Flip Chips, Connectors

* BGA to 0.2mm

Our capability for PCB:

Rigid PCB Fabrication Capability

Max Layer count: 2-32 layers

Max Panel Size: 1350mm*530mm (53.1496″*20.8661″)

Min Finished Board Thickness: 0.15mm (0.0059″)

Max Finished Board Thickness: 6.50mm (0.2559″)

Min Core Thickness: 0.05mm (0.0020″)

Min Cu Thickness(Base): 8um (1/4 OZ)

Drilling Hole to Hole Accuracy: ± 0.05mm (± 0.0020″)

Routing Edge to Edge Accuracy: ± 0.05mm (± 0.0040″)

Stamping Edge to Edge Accuracy: ± 0.075mm (± 0.0030″)

V-cut Edge to Edge Accuracy: ± 0.10mm(± 0.0039″)

PTH Tolerance: ± 0.075mm (± 0.0029″)

NPTH Tolerance: ± 0.05mm (± 0.0020″)

Min Drill Size: 0.15mm (0.0059″)

Min Drill Size: ± 0.075mm (0.003″)

Aspect Ratio: 15:1

Trace Width Tolerance: ± 10%

Min Trace Width: 0.05mm (0.0020″)

Registration (O/L): ± 0.038mm (± 0.0015″)

Min Solder Mask Dam Width: 0.076mm (0.0030″)

S/M Registration Tolerance: ± 0.025mm (± 0.0015″)

Max Test Points/Board(Universal ET): 100,000

Min SMT/QFP Pitch: 0.250mm (0.0100″)

Min BGA Pitch: 0.30mm (0.0118″)

Max Board/Array Size (Universal ET): 430mm*1280mm (16.93″*50.39″)

Impedance Control Tolerance: ± 5%

HDI Structure 1+N+1 \ 2+N+2\3+N+3: Yes

FPC Manufacturing Capability

Layer Count: 1-16L

Max Panel Size: 250mm×540mm

Min Finished Board Thickness: 0.05mm

Min Trace Width: 0.03mm

Min Drill Size: 0.075mm

Min Cu Thickness (Base): 12um

Molding Tolerance: ±0.05mm

Testing Equipment

Kingsheng PCBA Tech offers a full range of testing service. Including: AOI(Automatic Optical Inspection) Function Testing In Circuit Testing Testing Jig Testing Service X-Ray for BGA Testing Printing Solder Paste Test Each board is carefull ... [more]

Components Chamber

To protect sensitive component, such as ICs, we store the components in electronics component chamber. Sensitive Electronics Components Chamber PCB Baking Oven Solder Paste Storage ... [more]

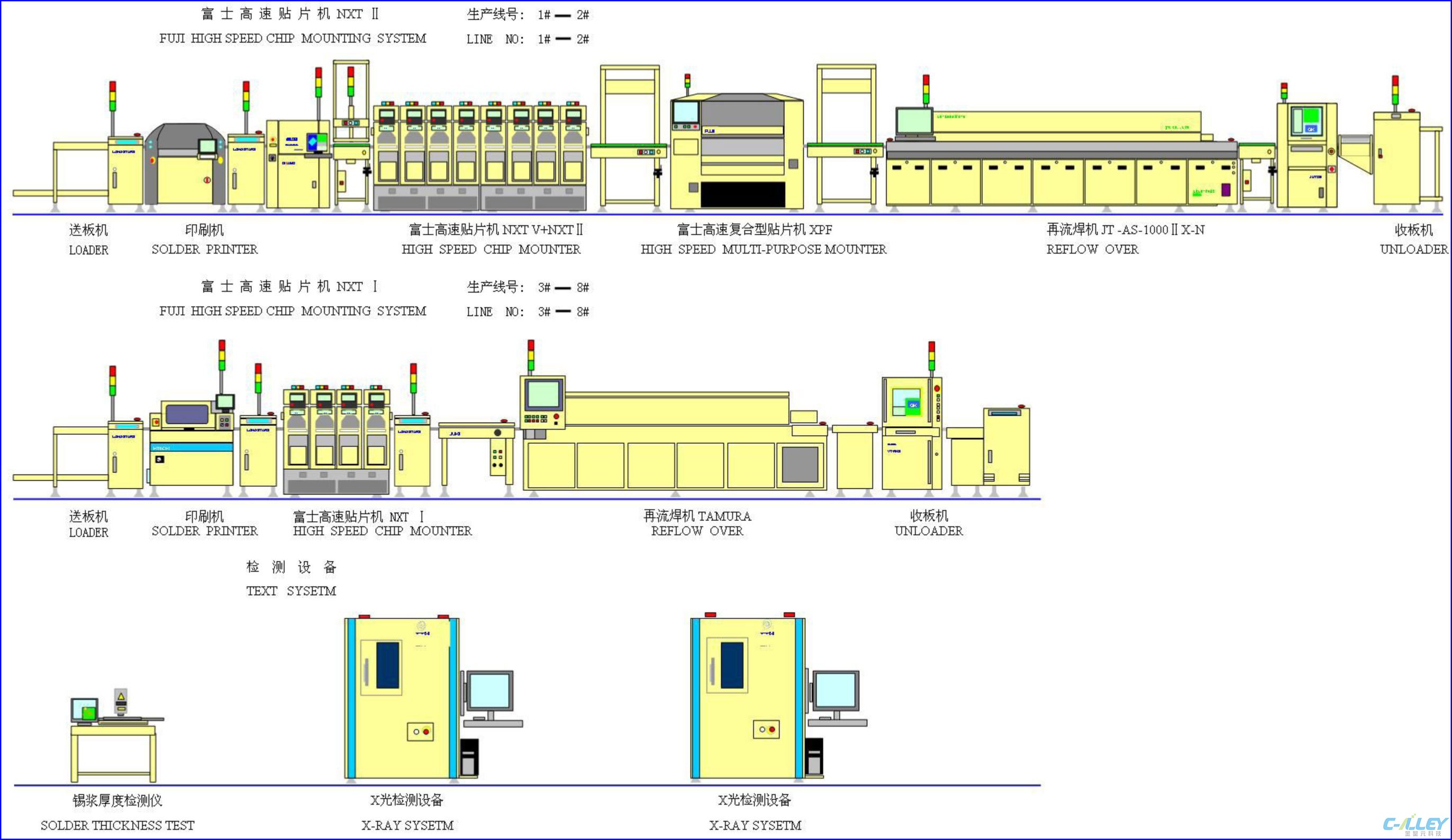

SMT Equipment

Advanced SMT Equipment: HITACHI Screen Printer FUJI NXT-Ⅱ FUJI XPF-L Modules Assembly Production Machines: 8 automatic Fuji SMT lines with both lead and lead free are available 2 DIP Dual wave soldering line 2 manual soldering product ... [more]